Table of Contents

Lime plastering is a traditional building technique that has been used for centuries to create durable and aesthetically pleasing interior and exterior finishes. In this comprehensive article, we will delve into the world of lime plastering, exploring the different types of lime plaster, its benefits, the steps involved in the application process, and common mistakes to avoid.

Whether you are a homeowner looking to renovate, a contractor seeking to expand your skills, or simply curious about this time-honored craft, our guide will provide you with valuable insights and practical knowledge to understand and master the art of lime plastering.

What Is Lime Plastering?

Lime plastering is a traditional building material that has been utilized for centuries in historical construction and is renowned for its versatility and eco-friendly properties.

Its historical significance dates back to ancient civilisations where it was extensively used and admired for its durability and breathability. Lime plaster, a lime-based material, has been a sustainable choice due to its minimal environmental impact. Its composition, typically consisting of lime, water, and sometimes additives like animal hair or marble dust, results in a material that can regulate moisture and withstand natural weathering.

The application of lime plaster requires skill and craftsmanship, as it is often applied in thin layers, allowing for a natural aging process that enhances its aesthetic appeal. The breathable nature of lime plaster also contributes to healthier indoor environments by reducing moisture buildup and inhibiting mold growth, making it a sought-after choice for modern eco-friendly construction projects.

Explore: How To Plaster A Wall

What Are The Different Types Of Lime Plastering?

Lime plastering encompasses various types, including lime mortar, lime render, and lime stucco, each offering distinct characteristics and applications in construction and finishing walls.

Lime mortar, typically made from a mixture of lime, sand, and water, is renowned for its flexibility and high water permeability, making it an ideal choice for restoring historic buildings and creating a breathable surface.

Lime render, consisting of lime, sand, and other additives, is prized for its durability, weather resistance, and ability to provide a smooth and attractive finish.

On the other hand, lime stucco, with its decorative and ornamental capabilities, is often used for creating intricate designs and textures on exterior facades, adding a touch of elegance to architectural structures.

Hydraulic Lime Plaster

Hydraulic lime plaster is a sustainable building material that offers excellent adhesive properties, making it ideal for construction and restoration projects.

It is derived from limestone, and when mixed with water, it forms a strong bond with various surfaces. Its flexibility allows for expansion and contraction, making it suitable for historic buildings and modern structures alike. Hydraulic lime plaster also provides a breathable surface, allowing moisture to evaporate, and preventing trapped moisture and mold. This makes it a preferred choice for eco-friendly and sustainable construction, contributing to a healthier indoor environment.

Non-Hydraulic Lime Plaster

Non-hydraulic lime plaster is favored for finishing walls due to its breathable nature, allowing moisture to evaporate and contributing to the creation of breathable walls.

This type of plaster is a sustainable and environmentally friendly choice for construction and restoration projects. Its ability to regulate humidity and prevent moisture build-up makes it ideal for maintaining a healthy indoor environment. Non-hydraulic lime plaster offers exceptional durability, providing long-lasting protection to the walls whilst also adding a unique aesthetic appeal. Its versatility allows for diverse finishing options, making it a popular choice among architects and designers for creating visually appealing and functional spaces.

Lime Putty Plaster

Lime putty plaster, often used in historic preservation, offers a traditional and aesthetic finish, providing a timeless appeal with its application of lime wash and contribution to historic preservation efforts.

This traditional building material has been favored for centuries due to its remarkable breathability and natural antiseptic properties, making it an ideal choice for preserving the structural integrity of heritage buildings. Limewash, derived from lime putty, not only enhances the visual charm of historic structures but also acts as a protective barrier against moisture, helping to thwart decay and prolong the longevity of these architectural treasures.

What Are The Benefits Of Lime Plastering?

Lime plastering offers several advantages, including its eco-friendly nature, natural composition, and its contribution to sustainable and breathable walls in lime-based construction.

It is a sustainable building material that is free from chemicals and synthetic components, making it an excellent choice for environmentally conscious construction. Lime plastering allows walls to breathe, preventing moisture build-up and promoting a healthier indoor environment. Its natural composition also makes it a compelling option for those seeking a more eco-friendly approach to building materials.

By using lime plastering, builders can contribute to the promotion of sustainable and natural building materials, aligning with the increasing demand for environmentally responsible construction practices.

Breathability

One of the primary benefits of lime plastering is its breathability, which is crucial for preserving the integrity of heritage buildings and ensuring the longevity of the construction.

This is especially significant for historical constructions as it allows moisture to escape, preventing the buildup of dampness which can lead to structural damage. By enabling the building to ‘breathe,’ lime plastering contributes to the preservation of the building’s original materials and supports the sustainability of heritage structures.

Its role in maintaining a healthy internal environment and minimizing the risk of decay makes it an indispensable element in the conservation and restoration of heritage buildings.

Flexibility

Lime plastering offers flexibility, especially when using lime mortar, allowing for structural movement and minimizing the risk of cracks or damage in construction projects.

This versatility makes lime plastering particularly suitable for older or historic buildings, where structural shifts are more prevalent. Lime mortar’s ability to accommodate these movements reduces the likelihood of unsightly cracks or the need for frequent repairs. The breathable nature of lime plaster ensures that any moisture within the underlying structure can escape, preventing potential dampness and rot issues.

It’s no wonder that lime plastering has been a preferred choice for centuries, standing the test of time as a durable and adaptive construction method.

Longevity

Lime plastering, especially when utilizing lime render, offers exceptional durability, making it a sustainable building material choice for long-lasting and resilient construction finishes.

This natural material has been used for centuries in construction due to its ability to withstand the test of time, providing enduring strength and resilience. Lime plastering not only contributes to the historical beauty of architecture but also aligns with modern sustainability goals by reducing the overall environmental impact.

Its unique composition allows for breathability, reducing moisture build-up and preventing mold and mildew growth, thus promoting healthy indoor environments. The use of lime plastering not only ensures a durable and long-lasting finish but also reflects a commitment to sustainable building practices.

Aesthetics

The aesthetic appeal of lime plastering, enhanced by the application of lime stucco, contributes to the timeless and elegant appearance of constructions, promoting the use of lime-based materials in architectural designs.

It’s fascinating how lime stucco, with its ability to create a smooth and luxurious finish, adds a touch of sophistication to buildings. The versatility of lime-based materials allows for the incorporation of intricate designs and artistic expressions, further elevating the aesthetic value of architectural spaces. The natural, earthy tones of lime stucco also blend seamlessly with various architectural styles, making it a preferred choice for those seeking an elegant and enduring aesthetic for their constructions.

What Are The Steps To Lime Plastering?

The process of lime plastering involves several key steps, including:

- Preparation of the surface

- Mixing the lime plaster

- Applying multiple coats using lime mortar or lime putty

- Finishing the surface to achieve the desired texture and appearance

To prepare the surface, it is essential to remove any existing loose material, clean the area thoroughly, and dampen the surface to create a suitable base for the lime plaster.

The mixing process involves combining the lime with sand and water to create lime mortar or using lime putty, ensuring a smooth and consistent mixture.

When applying the plaster, it is crucial to work in thin layers, allowing sufficient drying time between coats. This process is vital in lime-based construction, as it contributes to the durability and aesthetic appeal of the finished surface.

Preparation Of The Surface

Preparation of the surface is a critical initial step in lime plastering, ensuring the proper adhesion and compatibility of the lime-based material with the substrate for a durable and long-lasting finish.

It is essential to understand that the surface must be clean, and free from dust, grease, and any previous coatings to allow the lime plaster to bond effectively. The substrate’s moisture level should be tested to prevent any moisture-related issues after application.

Properly preparing the surface also involves repairing any cracks, holes, or irregularities to create a smooth and uniform base for the lime plaster. Neglecting these crucial preparatory steps can lead to poor adhesion, cracking, and premature failure of the lime plaster.

Mixing The Lime Plaster

The process of mixing the lime plaster, whether utilizing lime mortar or lime putty, is essential to achieve the desired consistency and workability for successful application and adhesion to the construction surface. Proper mixing ensures that the lime particles are evenly distributed throughout the plaster, promoting a strong, cohesive bond. This is especially crucial when working with lime plaster, as it directly impacts its durability and resilience.

Achieving the correct proportion of lime mortar or lime putty with water is vital, as it influences the setting time and the ability of the plaster to adhere securely. A well-mixed lime plaster enhances its plasticity, allowing for smooth and uniform application across the substrate.

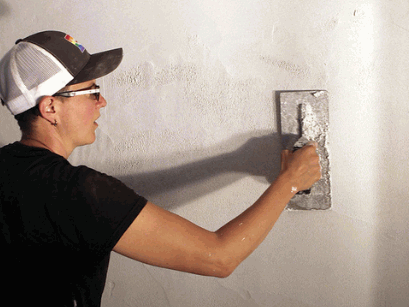

Applying The First Coat

The application of the first coat in lime plastering is a foundational step, establishing the base for subsequent layers and contributing to the structural integrity and aesthetics of the lime-based construction.

It plays a crucial role in providing a smooth and cohesive surface for the finishing coats to adhere to, ensuring a durable and visually appealing result. The first coat acts as a key element in creating a bond with the underlying substrate, promoting adhesion and preventing delamination. It aids in regulating moisture within the structure and contributes to the overall breathability of lime-based construction, which is essential for maintaining a healthy and sustainable living environment.

Applying The Second Coat

The application of the second coat, often utilizing lime render or lime stucco, further enhances the durability and aesthetic appeal of the lime plastering, creating a robust and visually appealing finish for the construction project.

This additional layer of lime render or lime stucco not only adds strength and resilience to the plaster but also contributes to its aesthetic charm. The second coat acts as a protective barrier against weathering and external elements, ensuring the longevity of the lime plaster. It allows for intricate detailing and a smoother finish, elevating the overall visual impact of the construction while maintaining the traditional allure of lime-based materials.

Finishing The Surface

The final step of finishing the surface in lime plastering involves the application of lime wash, contributing to the protective and aesthetic qualities of the lime-based material, ensuring a durable and visually appealing result for the construction project.

- This crucial step not only provides protection against weathering and decay but also imparts a stunning, soft glow to the surface.

- Limewash offers a breathable, flexible finish that allows moisture to escape while preventing the buildup of harmful substances.

- It helps regulate the temperature within the building, making it an environmentally friendly choice.

The natural pigments of lime wash offer a wide range of beautiful colors, providing endless possibilities for creating unique and striking visual effects on the completed surface.

What Are The Common Mistakes In Lime Plastering?

Whilst lime plastering offers numerous benefits, there are common mistakes to avoid, such as using the wrong type of lime, insufficient surface preparation, improper mixing, applying excessively thick coats, and neglecting proper humidity levels, all of which can affect the quality and longevity of lime-based construction projects.

Using the wrong type of lime, for instance, can lead to issues like poor adhesion and premature deterioration. Insufficient surface preparation, such as failure to remove dust, dirt, or previous coatings, can result in poor bond and durability. Improper mixing of lime mortar can compromise its strength and workability, impacting the overall stability of the plaster. Applying excessively thick coats can lead to cracking and uneven curing. Neglecting proper humidity levels during the curing process can result in inadequate carbonation, affecting the strength and durability of the plaster.

Using The Wrong Type Of Lime

Using the wrong type of lime can significantly impact the quality and performance of the plaster, affecting its compatibility with the construction substrate and compromising the structural integrity of the lime-based material.

Choosing the appropriate type of lime for plastering is crucial to ensure the desired chemical and physical properties. When the wrong type of lime is used, it can result in poor adhesion to the substrate, increased susceptibility to cracking, and reduced durability. The incorrect lime type may also lead to insufficient carbonation, affecting the overall strength and stability of the plaster.

Therefore, it is essential for construction professionals to understand the different types of lime and their respective applications in order to select the most suitable one for their specific plastering needs.

Not Preparing The Surface Properly

Inadequate surface preparation can hinder the adhesion and longevity of lime plastering, emphasizing the importance of thorough surface assessment and appropriate application of lime mortar or lime putty to ensure optimal results.

Proper preparation of the surface is crucial for creating a strong bond between the lime plaster and the substrate. It involves carefully evaluating the existing surface conditions, addressing any imperfections, and ensuring proper absorption for the lime mortar or lime putty.

This meticulous process sets the foundation for a durable and resilient plaster finish, enhancing its ability to withstand environmental factors and the test of time. The careful application of lime mortar or lime putty further reinforces the integrity of the plaster, contributing to its long-term performance.

Incorrect Mixing Of The Plaster

Improper mixing of the plaster can lead to inconsistencies in texture and performance, necessitating a meticulous approach to achieve the desired properties and durability for a successful application in lime-based construction projects.

This can result in a variety of issues, including poor adhesion, cracking, and reduced strength of the plaster mixture. Inconsistent mixing may also affect the overall aesthetic appeal of the lime plaster surface.

Therefore, it is crucial to carefully measure and mix the materials, maintaining the correct ratios of lime, sand, and water. This meticulous approach ensures that the plaster achieves optimal bonding, breathability, and resilience, essential for long-term structural integrity in lime-based construction projects.

Applying Too Thick Of A Coat

Applying excessively thick coats, particularly when using lime render or lime stucco, can compromise the structural integrity and aesthetic appeal of the plaster, necessitating a balanced and strategic approach to achieve the desired finish for the construction project.

Excessive thickness in lime plastering, notably with lime render or stucco, can lead to cracking, delamination, and poor adhesion, jeopardizing the overall strength and visual appeal of the surface. This could result in a significant negative impact on the longevity and durability of the plasterwork. Therefore, adopting a measured application technique is crucial for maintaining the integrity and enhancing the beauty of the plaster, ensuring its resilience against weathering and providing a pleasing finish for the architectural structure.

Failing To Maintain Appropriate Humidity Levels

Failure to maintain proper humidity levels during the curing process can compromise the strength and adhesion of the plaster, emphasizing the need for meticulous control of environmental conditions to ensure optimal performance in lime-based construction projects.

This meticulous control is crucial as lime plastering is sensitive to environmental factors. Inappropriate humidity levels can lead to inadequate carbonation, affecting the development of the plaster’s strength and durability. The consequences of such compromise extend to reduced adhesion and a higher susceptibility to damage. Therefore, ensuring the ideal humidity during the curing process is vital for the long-term performance of lime-based construction, contributing to the overall quality and resilience of the structure.